New Mills engineering firm recruited in Dyson’s bid to build 15,000 Covid-19 ventilators

and live on Freeview channel 276

Alken Engineering Ltd are aiming to turn out 10,000 custom-made components for Dyson’s specially-designed CoVent - by next week.

UK hospitals currently have access to just over 8,000 ventilators - however it is estimated more than 30,000 will be needed as coronavirus spreads further.

Advertisement

Hide AdAdvertisement

Hide AdThe machines support patients who can no longer keep their airways open - however Dyson’s new design addresses the specific needs of Covid-19 patients.

James Dyson - the company's billionaire founder - hopes to deliver the order to the Government in the first half of this month.

Since contacting Alken’s managing director Tristan Catterall last week, staff at the 45-year-old firm have been working late and early shifts to manufacture the components in time.

Group CEO Paul Coverley received a call from Dyson when an ex-colleague recommended the company and after agreeing on the design Alken immediately began working on samples.

Advertisement

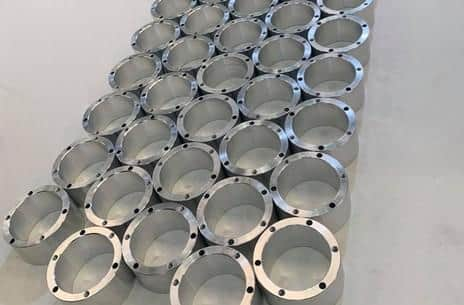

Hide AdThe company – working with New Mills firm 5-Axis has staff producing 600 of the 75mm aluminium housings along with 600 perspex lenses per day – and are set to increase production on a 24-hour shift pattern to hit the deadline.

Advertisement

Hide Ad

Alken’s directors told how they were ‘very proud and happy’ to be doing their part in the fight against coronavirus and ‘extremely humbled’ by their staff’s hard work.

Managing director Tristan said: “I’m very proud of the lads and the way they’ve accepted changing their hours - these have been difficult times for us as they have for every other company.”

Since the order for the parts arrived on Thursday last week Alken - who employ about 80 staff - have been racing to achieve it on schedule.

Advertisement

Hide AdAt present they are shipping over 1,000 units to Dyson’s software and technology hub in Bristol every day.

Workshop manager Chris Prodromis said: "We’re working hard everyday with Dyson to produce integral ventilator parts as quickly as we can – I’m proud of the lads at Alken.

“We all need to play our part.”